An In Depth Look at Glock Optic Cuts

Posted by Taylor Mullins on Dec 22nd 2024

A Short History On Glock Optic Cuts

Glocks are synonymous with rugged reliability. With a reputation like that, it is evident why Glocks have been frontrunners in duty-use handguns since the Glock 17 debuted in 1982 as one of the first polymer-frame pistols. With such widespread usage, it’s no surprise that they played a significant role in the early adoption of red dots on pistols for duty use, notably through the popularity of the "Roland Special" in the mid-2010s. To understand why it took so long for this setup to become mainstream, we need to examine the evolution of miniature red dots, starting in the 1990s.

The journey began with the Docter Optic, which saw limited use during the Global War on Terror, primarily as a piggybacked red dot mounted on the Trijicon ACOG. This innovation paved the way for Trijicon to develop the RMR (Ruggedized Miniature Reflex). The RMR struck a perfect middle ground between optic ruggedness and form factor. With these characteristics it could not only be mounted directly to pistol slides but it could withstand the recoil and force of the moving slide. which is why the RMR is widely credited with popularizing red dots on pistols.

As mentioned earlier, the first major instance of red dots gaining mainstream traction in the gun community came through the "Roland Special," a compensated Glock 19 equipped with a Surefire X300 weapon light and a Trijicon RMR. The Roland Special started off on the Primary and Secondary Facebook group and its creation is credited to a man named Chuck Pressberg. Chuck wanted to increase the performance of his Glock. He initially did this by changing the barrel on his Glock to a KKM barrel. This then progressed to adding the KKM compensator. Even though the Roland special initially only had the compensator and a light for one of Chuck's birthdays his friends got him an optic cut Glock 17. After some time he put both of those concepts together and got the modern day Roland Special, which is ubiquitously represented as having both a red dot and a compensator. At this point you're wondering how a gun made by a guy named Chuck got the nickname "Roland" Special. In short, it comes from the Dark Tower Series by Steven King one of the characters in the book who is a gunslinger named Roland Deschain. Over a decade after the Roland Special was on everyone's social media, the RMR remains one of the most popular pistol-mounted optics on the market.

Why Slide Milling For An Optic Cut?

Lately, pistol manufacturers have been releasing optic ready pistols. With Glocks, this line of pistols is called the MOS. An example of this naming scheme would be Glock 19 MOS. The way these pistols come optic ready is through a system of plates that always match with the pistol end of the plate but multiple plates are needed for different optics. For example, one can have a Glock 17 MOS and have an RMR plate which would allow for the RMR footprint and then another plate for something like an Aimpoint Acro. However, In my, and many others opinion there are drawbacks to this sort of optic ready system. Below we will be talking about why and how direct milling for an optic is superior when given the option.

Direct Milling vs Optic Plate

When it comes to mounting optics, nothing is more important than the security of the optic fit. Does it retain zero? Does the mount break? What is the height of the mount? These are all critical questions you should not only ask yourself but also research thoroughly when purchasing any optics mounting platform. Between optic plates and direct milling—at least when it comes to Glocks—you should always choose direct milling for optic cuts. This is because it can reliably answer all three of the questions above, and direct milling is consistently the more robust option.

Does it retain zero? Yes. The optic is not only screwed into the slide but also secured by the shelf created by the slide itself at both the front and the back of the optic to hold it in place. Even better, many optic and slide combinations allow for a third form of security through recoil bosses, which act as a male-and-female pairing between the slide and the optic. While most plate systems include some form of recoil boss system, the main failure point lies in the plate’s thickness and material. This introduces more variability in performance compared to direct milling, which is far more consistent.

Does the mount break? How can a mount break if there isn’t one? In short, if the slide work has been done for a specific optic cut, the optic mounts directly into the slide. This means there are really only two components that can fail in this system: the slide or the optic. Adding a plate introduces an additional failure point. Any plate that can’t withstand the force of recoil or the leverage of the optic on top will either bend or outright break the screws holding it in place. It’s worth noting that not all optic plates are created equal, and many are reliable. However, as with scope mounts, plate quality varies, and some designs are inherently weaker.

What is the height of the mount? This is one area where a quality plate will never match direct milling. By adding a plate, you increase the height at which the optic sits on the pistol. This means that if you want to co-witness iron sights with this setup, you’ll need to find very tall iron sights. Additionally, using a plate can alter how you present the firearm to align with the red dot, especially if you’re accustomed to traditional iron sights. Direct milling, on the other hand, keeps the optic closer to the slide, making any adjustment in presentation less dramatic. Regardless of the setup, both systems can be adapted to through proper training and practice.

In Summary: Adding a red dot to your handgun will enhance its performance by making it much more efficient. However, it’s important to note that practice is still necessary to improve your skills with the pistol. That being said, a red dot will help you identify mistakes more easily, is simpler to use, and unlocks your pistol’s potential for night vision use!

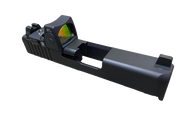

Optic Cuts For Glock at North Sea Machine

When it comes to Glock Optic Cuts. You may notice that we only have two listings on our website: Glock Optic Cut (Excluding G43/48) and Glock G43/48 Optic Cut. We designed this to make it as simple as possible for you to find what you're looking for. You either have a slimline Glock or a standard-width Glock. From there, it’s as straightforward as telling us which optic you have, your rear sight preference, and whether you’d like the slide coated. Please note that we cannot perform optic cuts for Glock 42s due to how thin their slides are.

If you own a slimline Glock, such as the Glock 43 or Glock 48 series, you may notice they don’t offer the same range of optic choices as standard-width Glocks. This is due to the reduced milling surface available on the slimmer slides, so we’ve only listed options that can be mounted.

If you want an optic cut for your Glock (not 43/48 series) click here

If you own a Glock 43/48 series handgun and want an optic cut for it click here

Summary

Glocks have earned their reputation as rugged and reliable handguns since Gaston Glock Debuted the Glock 17 in 1982. Over the years, advancements in both firearms and optics have made it possible to mount miniature red dot sights directly onto slides, revolutionizing handgun performance. One of the earliest and most influential setups, the "Roland Special," gained popularity in the mid-2010s, sparking widespread interest in red dots for pistols.

Today, red dots are mainstream, with manufacturers releasing optic-ready handguns to meet the growing demand. However, not all mounting systems are created equal. Direct milling offers a superior solution compared to optic plates, providing greater durability, a lower profile, and enhanced reliability in retaining zero. At North Sea Machine, we simplify the process with two streamlined options for Glock optic cuts: one for standard-width models and another for slimline Glocks like the 43/48 series. Each cut is tailored to your optic, sight preferences, and coating needs, ensuring precision and performance.

Whether you're upgrading for competitive shooting, self-defense, or duty use, adding a red dot to your Glock unlocks new potential—but remember, practice is key to mastering the system.

If you would like to view our Glock optic cuts, click here

Third Party Information

- If you would like to learn more about the history of optics on handguns check out this blog and video from MidwayUSA.

- More of a reader? Here is a blogpost from Guns and Ammo about the history of pistol red dots.

- Interested in the Roland Special? Click here to watch or listen to the Primary and Secondary modcast featuring Chuck Pressberg. In the modcast Chuck talks about the birth of the legendary pistol.

- Want another opinion on optic plates vs direct milling? Here is a video where Lucas from Trex Arms gives his thoughts.